Silicon

Silicon metal is widely used to produce Aluminum alloy. This is because silicon can improve the castability, strength, and hardness of the alloy.

It also reduces the shrinkage of the metal during solidification, which results in better surface finish and overall quality of the final product.

Additionally, silicon can increase the resistance of the alloy to corrosion and wear, making it more durable and long-lasting.

Due to these properties, silicon metal is an essential component in many industries, including automotive, aerospace, and construction.

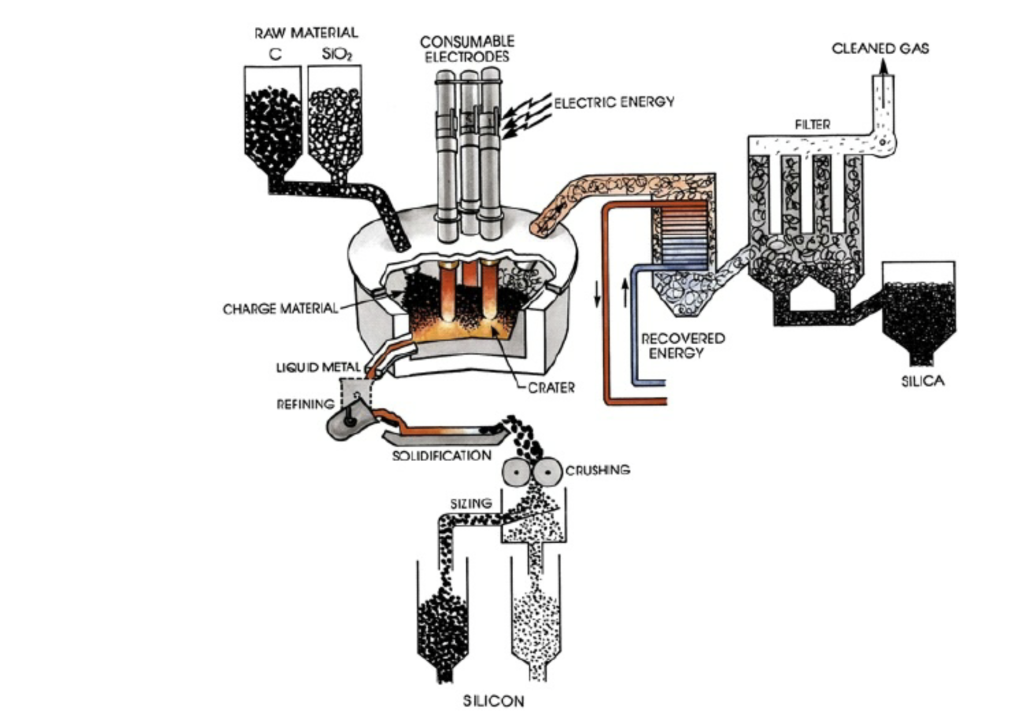

Electric Arc Furnace

Silicon Metal is the key element in Photovoltaic industry

Solar cells are electrical devices that convert light energy into electricity. Various types of wafers can be used to make solar cells, but silicon wafers are the most popular. That’s because a silicon wafer is thermally stable, durable, and easy to process.

Silicon is also a crucial element in the manufacturing of semiconductors, which are used in electronic devices such as computers, smartphones. The unique properties of silicon, including its ability to conduct electricity and resist heat, make it an ideal material for producing these vital components. The semiconductor industry is constantly evolving, and the demand for high- quality silicon continues to grow. Its unique properties make it an essential component in the production of high-quality and efficient products, and ongoing research is unlocking new and exciting uses for this remarkable element. Silicon color is dark gray and its atomic number is 14 also in group 14 of periodic table. 27% of earth crust is consist of Silicon and it is the second most abundant element on earth. Naturally it is found as Silicon dioxide SiO2.

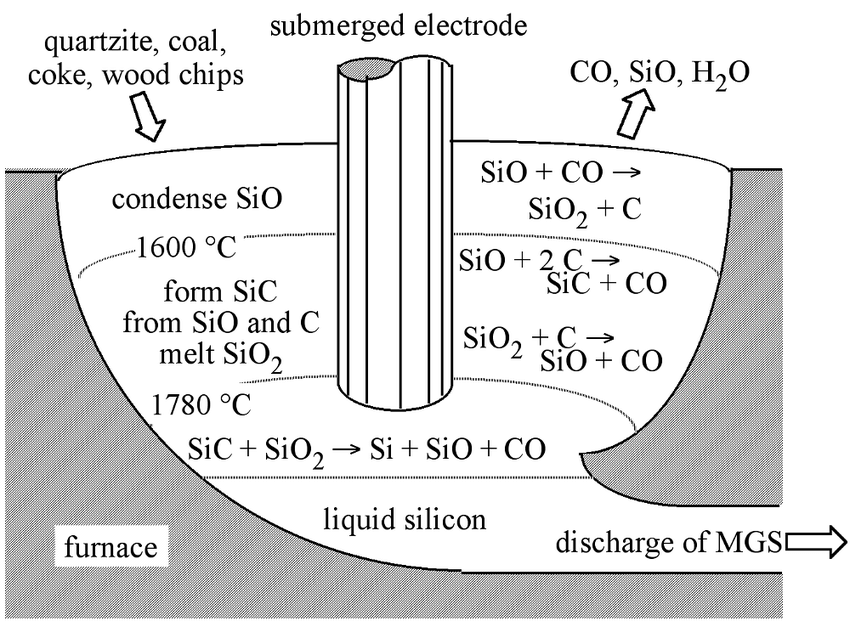

SiO2 and Carbon as row material in furnace arc

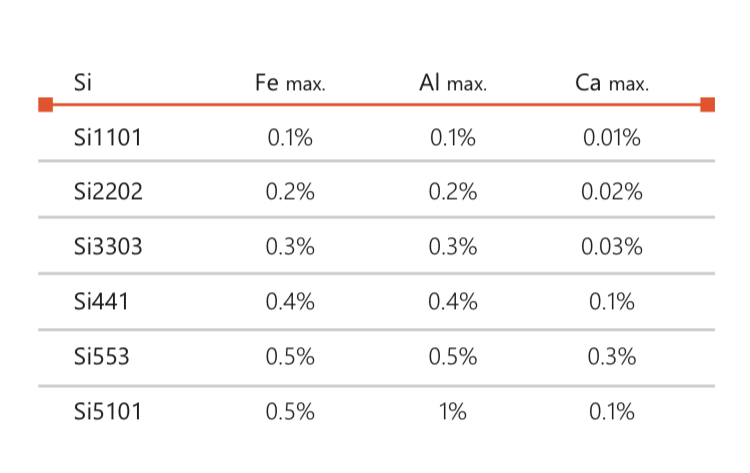

Grades of Silicon:

Silicon metal grades typically vary based on their purity levels and intended applications. Some common grades include:

1. Metallurgical Grade Silicon: Generally lower in purity (around 98-99%), used in the production of alloys like aluminum-silicon and ferrosilicon.

2. Solar/PV Grade Silicon: Higher purity levels (99.9999% or higher) specifically designed for the semiconductor industry and solar cell production.

3. Electronic Grade Silicon: Extremely high purity (99.9999% or higher) suitable for electronic applications like semiconductor manufacturing.

Each grade serves different industries and applications, with purity being a key distinguishing factor.

Metallurgical Grade Silicon: